Penope -Machines and Equipment for House Industry

PENOPE brand’s element tables, multifunction bridges, notching saws and other special equipment have been manufactured in Finland. Taking also into account the woodworking machines which we represent, we can offer efficient and individual wood element production lines or entire house construction plants as well as their design services. Also the individual machines and intensification of existing production by means of automation are part of our operations.

Element Tables

PENOPE element tables are known for their stable structure and high quality. Tables are equipped with servo driven conveyor belts to transfer elements from one table to another. Due to rubber coated belt and servo control, the surface of the element is not damaged during transfers. Tables can be equipped with fixed or height adjustable side pins according to purpose. If necessary, it is possible to attach to the framing table a wagon for the nailing tools for the heavy framing nailers. Lifting tables and receiving tables, capable of being turned hydraulically, are centrally controlled by the line control center. Each table can also be controlled separately by means of the remote control.

Multifunction Bridges

PENOPE HYBRID is an efficient multifunction bridge for the internal and external working phases of wood element production. When necessary, bridge can be manually, semi-automatically or fully automatically operated. It can be equipped with different kinds of nailing tools, screwdrivers, milling unit, glue spreader or other special tools. Penope Hybrid multifunction bridge contains several innovative solutions, such as identification of the nailing line positions by means of the luminescence sensor, automatic opening identification and laser positioning. Bridge can be installed on a new production line or integrated into existing element table line and it is equipped with the efficient dust extraction filter.

Element Production Lines

PENOPE -element production lines consist of element tables and, if necessary, multifunction bridge and other equipment, attached to the tables. Production line will be designed in full cooperation according to customer’s needs.

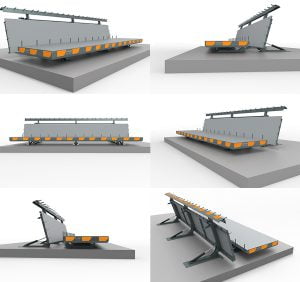

Butterfly Tables

On PENOPE – butterfly tables it is possible to manufacture special elements, like pediments, roof and wall elements etc.

- Lengths 6, 8, 10 and 12 m

- Width 2200 mm – 3500 mm

- Width control Hydraulic

- Element thickness 70 – 350 mm

- Tilting 75 and 90 degrees

- Upper pins removable

Notching Saw

PENOPE HL 400 -notching saw is designed to make notches at the end of pieces, for ex. for jointing the upright studs. The work piece is clamped pneumatically and the notch is cut by using two circular blades. The machine operation is controlled by the means of a foot pedal.

Technical data

- Notch depth 30 – 125 mm

- Notch length 10 – 400 mm

- Stud width 0 – 300 mm

Advantages: The saw processes the notches efficiently and precisely. Flexible operation and quick adjustments. Easy to use. The machine is controlled by means of a foot pedal.

Other Products

When necessary, we design an entire house construction plant and supply all other machinery and equipment from our range of woodworking machines:

- crosscut saws

- insulation saws

- mineral wool balers

- panel sawing machines

- assembly tables for window elements

- boom cranes

- plastic roll racks

- laser indicators

- shredders

- painting devices

- dust extraction equipment

- humidifiers

- conveyor solutions

Contact

Finland, Baltic countries, Russia

Heikki Laine

heikki.laine@penope.fi

www.penope.fi

+358 500 355151

Sauli Lehtonen, projects

sauli.lehtonen@penope.fi

+358 40 673 8700

Sweden, Norway, Denmark and German-speaking countries

Erik Nord

erik.nord82@gmail.com

www.bnc-maskin.se

+46 72 70 17 300

Development and export project of Penope Oy

Aim of this project was to start export of prefabricated house element line products to Russia, Sweden, Estonia, Latvia and Lithuania.

During this Project Penope has sold the element line products to Finland and also to Sweden, and the markets are expanding to whole Europe.

Russia, Latvia and Lithuania haven’t got a culture of Wood house production and that is the main reason why there is no demand for this kind of products.